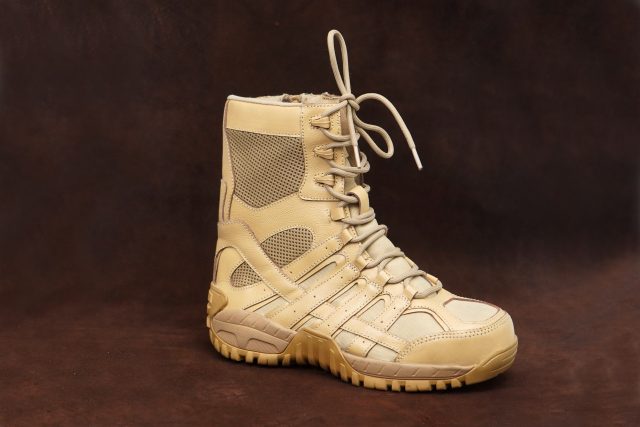

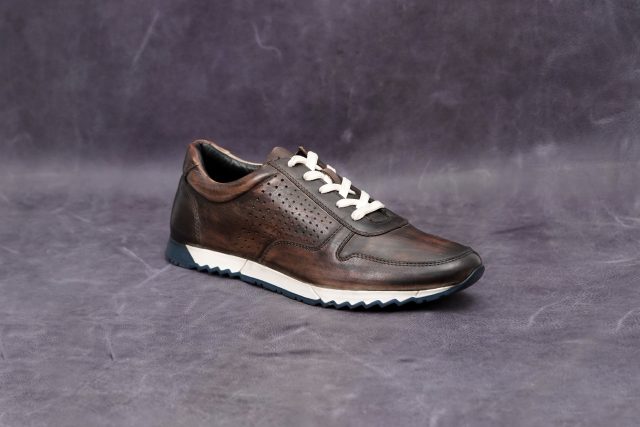

Welcome to Alig Tannery: Where Tradition Meets Excellence in Leather Craftsmanship

At Alig Tannery, we are dedicated to producing the finest leather, combining time-honored craftsmanship with modern innovation. With decades of experience, our commitment to quality and attention to detail is evident in every piece of leather we produce.Our leather collection is crafted from the highest quality hides, sourced from trusted suppliers who share our values of sustainability and ethical practices. We offer a wide range of leather types, each tailored to meet the diverse needs of our customers.Our leathers are not just materials—they are the foundation of premium products that stand the test of time. Whether you’re in the market for upholstery, fashion, automotive, or bespoke leather goods,Alig Tannery is your trusted partner.Experience the unmatched quality and versatility of Alig Tannery leather. We invite you to explore our collection and discover why we are a preferred choice for artisans, designers, and manufacturers worldwide.

Experience of Decades, Devotion of Generations…. Products for THE MOMENT

Three generations of Passion, Devotion and Tradition instils quality & values to everything at ALIG’s Production. Tannery Division backed by 4 units produces a range of high quality leather in various thicknesses and finishes for SHOE, UPHOLSTERY & LEATHER GOODS industry. Using INDIAN & European Raw Hide, It produces 25million square feet of Finished Leather annually with a strong presence in domestic market and exporting to 18 countries.

MAKING LEATHER: Input & Modern Procedures:Cautious marketplace is always looking for quality products, meeting stringent International Standard, We use suppliers of high profile and international reputation enabling us to be step up with the global aspirations and visions, making regulations such as REACH & JIS our production standard. Every Input is tested and complied in our own In-house LAB to an acceptable standard before putting into Production.

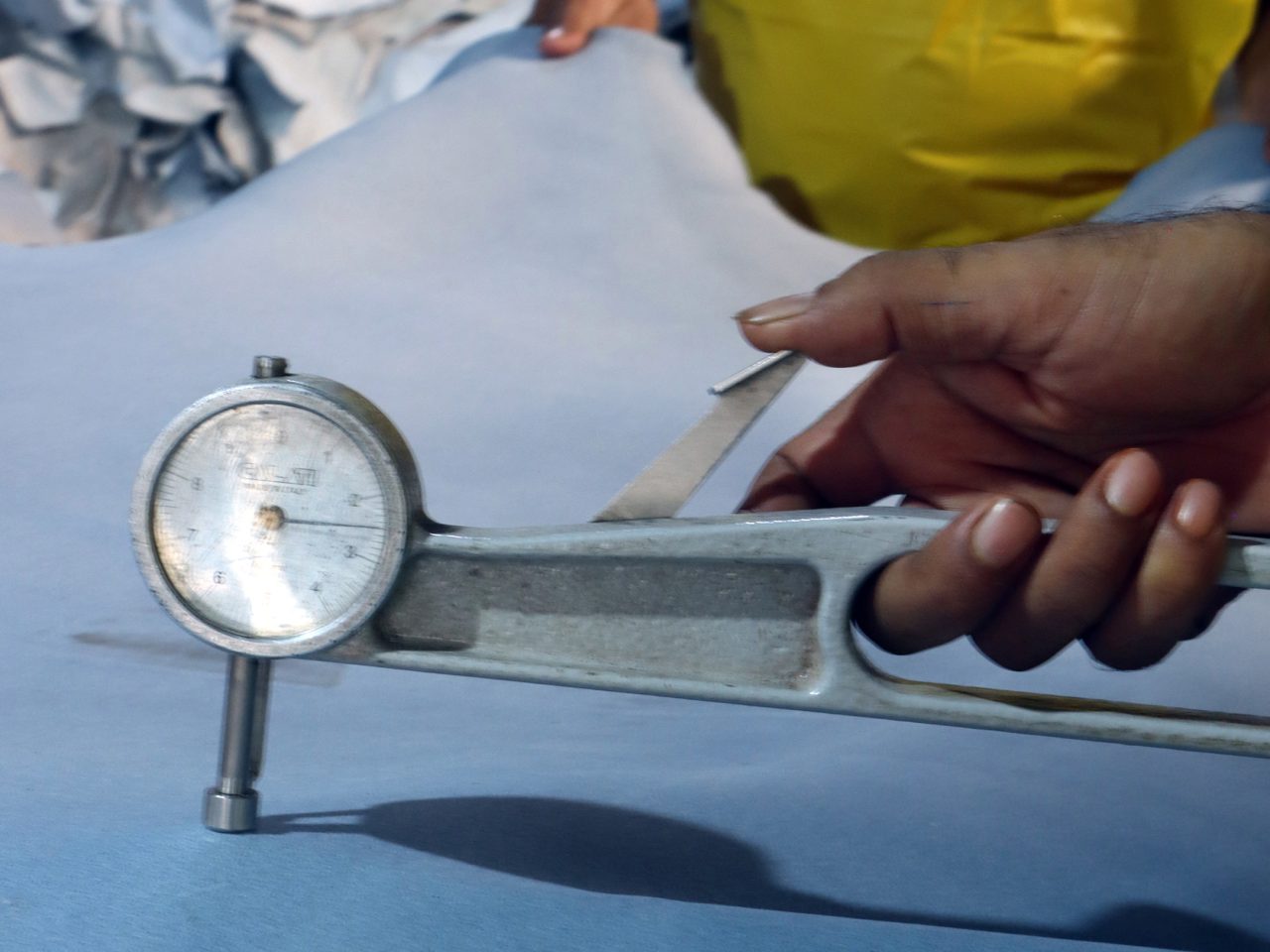

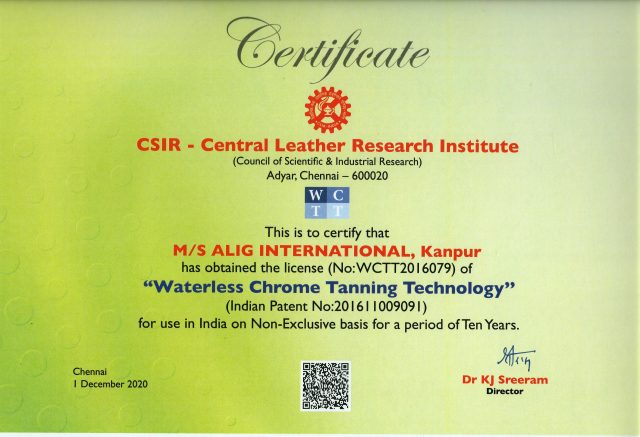

INNOVATION TO FASHION: Bringing Creativity to the Market:Since inception, R&D has been a passion at Alig. Product innovation entwined with the latest fashion trend makes our products not only creative but also commercially preferable. Standardization and consistency in production is our primary goal met by using cutting edge technology such Color Spectrometers, Auto Dosing systems etc.

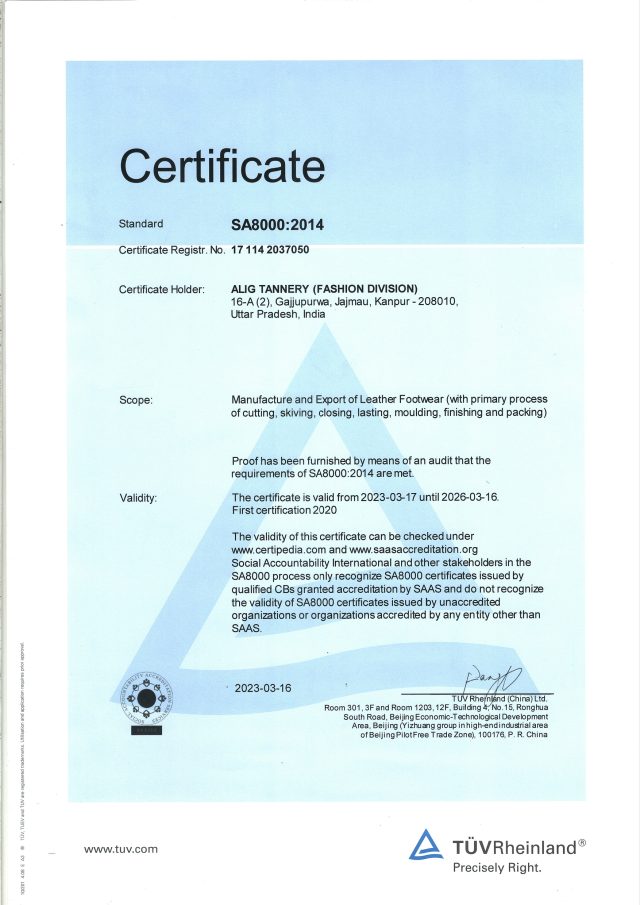

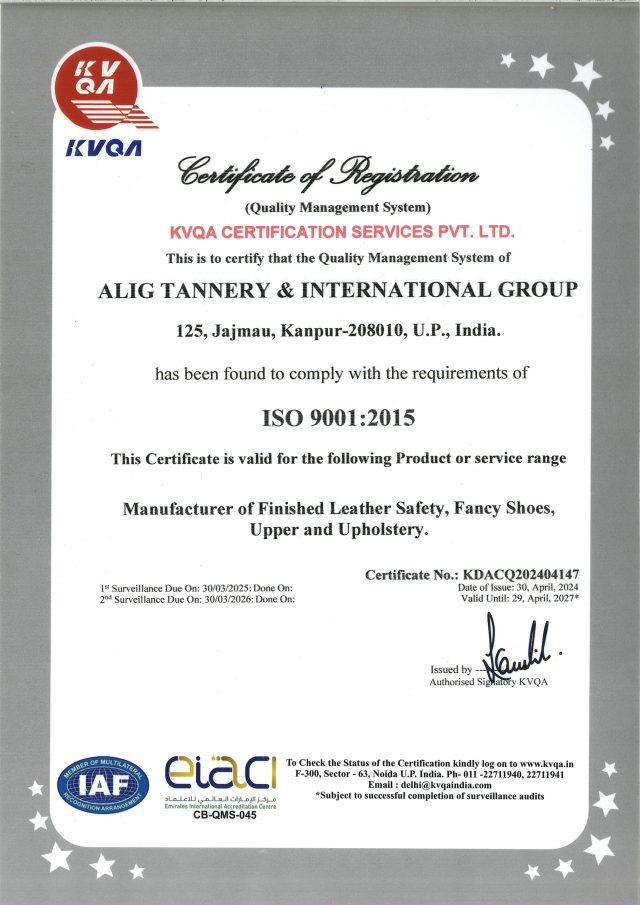

COMPLIANCE STANDARD: Regulation & Compliance:Modern infrastructure & disciplined workforce has helped us in consistently meeting International regulations in Production & Environmental practices, making customers’ confident working with us by sharing a common vision of Safer & Greener Future.

Testing and R&D!

Introduction

At Alig Tannery, quality is at the core of everything we do. Our commitment to excellence is reflected in every piece of leather we produce, ensuring that our customers receive products that meet the highest industry standards. Our Quality Control (QC) process is meticulously designed to monitor and maintain the integrity of our leather from raw material to finished product.

1. Raw Material Inspection

The foundation of high-quality leather starts with premium raw materials. Our QC team conducts a thorough inspection of hides and skins upon arrival at the tannery. This includes:

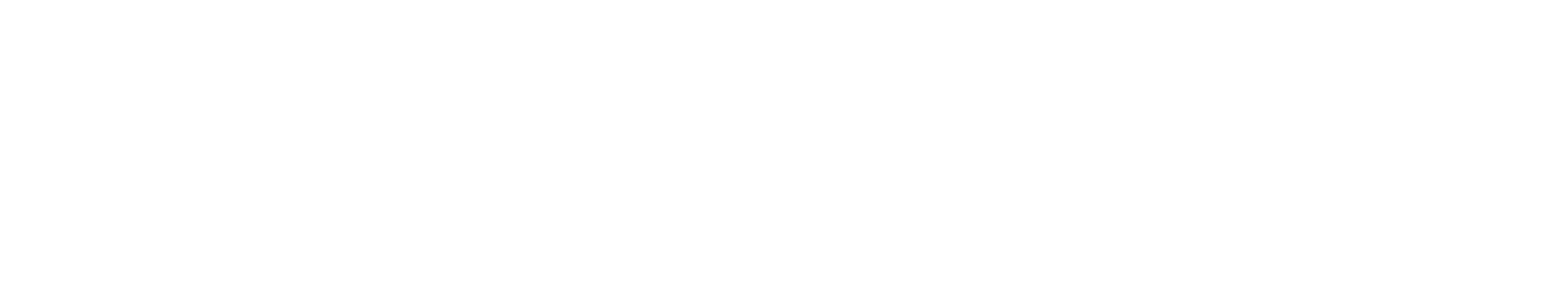

Grading: Assessing the hides for size, thickness, and defects such as scars, holes, or grain irregularities.

Traceability: Verifying the source of the raw materials to ensure they meet ethical sourcing standards.

Moisture Content Analysis: Measuring moisture levels to prevent issues like decay or excessive shrinkage during processing.

2. Tanning Process Monitoring

During the tanning process, our QC team continuously monitors various parameters to ensure consistency and quality. Key aspects include:

Chemical Control: Precise measurement and monitoring of chemicals used in tanning, including lime, chrome, and vegetable tannins.

pH Levels: Regular testing of pH levels during the tanning and dyeing process to ensure the leather develops the desired characteristics.

Temperature and Time Control: Monitoring the temperature and duration of each process stage to prevent over-tanning or uneven treatment.

3. Post-Tanning Quality Checks

Once the tanning process is complete, the leather undergoes several post-tanning quality checks, including:

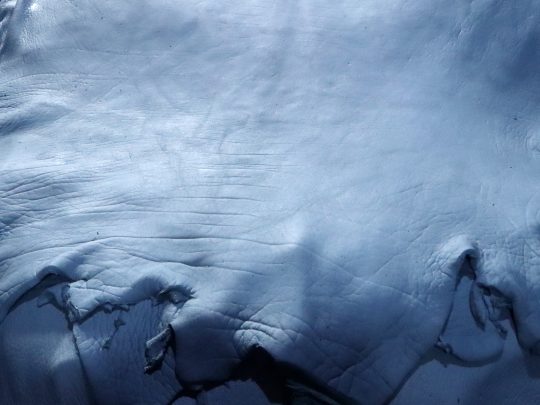

Thickness Measurement: Using calipers to ensure uniform thickness across the entire hide.

Color Consistency: Visual and spectrophotometer-based assessments to verify even color distribution and adherence to customer specifications.

Tensile Strength Testing: Ensuring the leather meets the required strength and durability standards through rigorous testing.

4. Finishing Process Control

The finishing process is where the leather gains its final appearance and texture. Our QC team ensures that each step meets our exacting standards:

Surface Inspection: Checking for imperfections such as uneven coating, scratches, or blemishes on the finished leather surface.

Flexibility and Softness Testing: Assessing the leather for the desired level of softness, flexibility, and feel, particularly important for luxury goods.

Water Resistance Testing: Performing water resistance tests on treated leathers to ensure they meet performance standards.

5. Final Product Inspection

Before the leather is packed and shipped to customers, it undergoes a final inspection:

Dimensional Accuracy: Ensuring the leather is cut and trimmed to the correct dimensions as per customer orders.

Packaging Inspection: Verifying that the leather is properly packaged to prevent damage during transportation.

Documentation: Ensuring all quality control documentation is complete, including certificates of analysis, inspection reports, and traceability records.

6. Continuous Improvement

At Alig Tannery, we believe in continuous improvement. Our QC team regularly reviews processes and feedback to identify areas for enhancement:

Customer Feedback Integration: Listening to customer feedback to refine our processes and meet evolving market demands.

Employee Training: Ongoing training programs for QC staff to keep them updated on the latest industry standards and technologies.

Sustainability Audits: Conducting regular audits to ensure our processes are environmentally sustainable and compliant with regulations.

Conclusion

Quality is not just a goal at Alig Tannery; it’s a promise. Through stringent quality control measures at every stage of production, we guarantee that our leather products meet the highest standards of excellence, ensuring customer satisfaction and long-term trust.

Water conservation is vital in leather tanning to reduce costs and minimize environmental impact. Below are key methods for conserving water:

- Recycling & Reusing Water: Install systems to recycle water from soaking, tanning, and dyeing processes. Reuse treated wastewater for non-critical operations.

- Optimizing Process Design: Use low-float systems to reduce water in soaking and liming. Batch hides to minimize water usage in washing and rinsing.

- Efficient Water Management: Use automatic valves and flow meters to control and monitor water usage in real-time.

- Closed-Loop Systems: Recycle water and chemicals within the tanning process to cut down fresh water needs.

- Chemical Management: Use enzymes and concentrated chemicals to reduce water consumption during soaking and liming.

- Rainwater Harvesting: Collect and store rainwater for tannery use to further reduce fresh water demand.

- Maintenance & Upgrades: Regularly inspect and fix leaks. Upgrade to water-efficient machinery.

- Training & Awareness: Educate staff on water-saving techniques and create a culture of conservation.

- Wastewater Treatment: Install advanced treatment systems like reverse osmosis to reuse wastewater within the tannery.

By adopting these practices, tanneries can significantly reduce water consumption and operate more sustainably.

The leather industry is shifting towards eco-friendly chemicals to reduce environmental impact. Here are some key sustainable alternatives:

- Chrome-Free Tanning: Use of alternative tanning agents, instead of chromium, lowering TDS and Minerals in effluents.

- Vegetable Tannins: Derived from natural sources like tree bark, offering biodegradable tanning with no harmful chemicals.

- Syntans: Synthetic organic tannins that reduce chemical waste and improve water management.

- Enzyme-Based Chemicals: Used in dehairing and bating, reducing water pollution and chemical use.

- Phosphate-Free Degreasers: Minimize water contamination and are biodegradable.

- Water-Based Finishes: Replace solvent-based coatings, reducing VOC emissions and improving air quality.

- Bio-Based Fatliquors: Made from plant oils, reducing reliance on petroleum.

- Eco-Friendly Dyes: Azo-free and heavy metal-free dyes reduce toxic runoff.

These sustainable chemicals improve leather production’s environmental footprint while ensuring safer practices and better quality.

Saving Water